2130 products

Showing 1 - 24 of 2130 products

PipingNow.com is your premier destination for all things valves, offering an extensive array of options tailored to your specific needs. We understand the critical role valves play in various applications, from commercial to industrial and marine environments. That's why we stock a comprehensive selection of valves crafted from Stainless Steel, Carbon Steel, and Bronze, ensuring durability and performance in every setting.

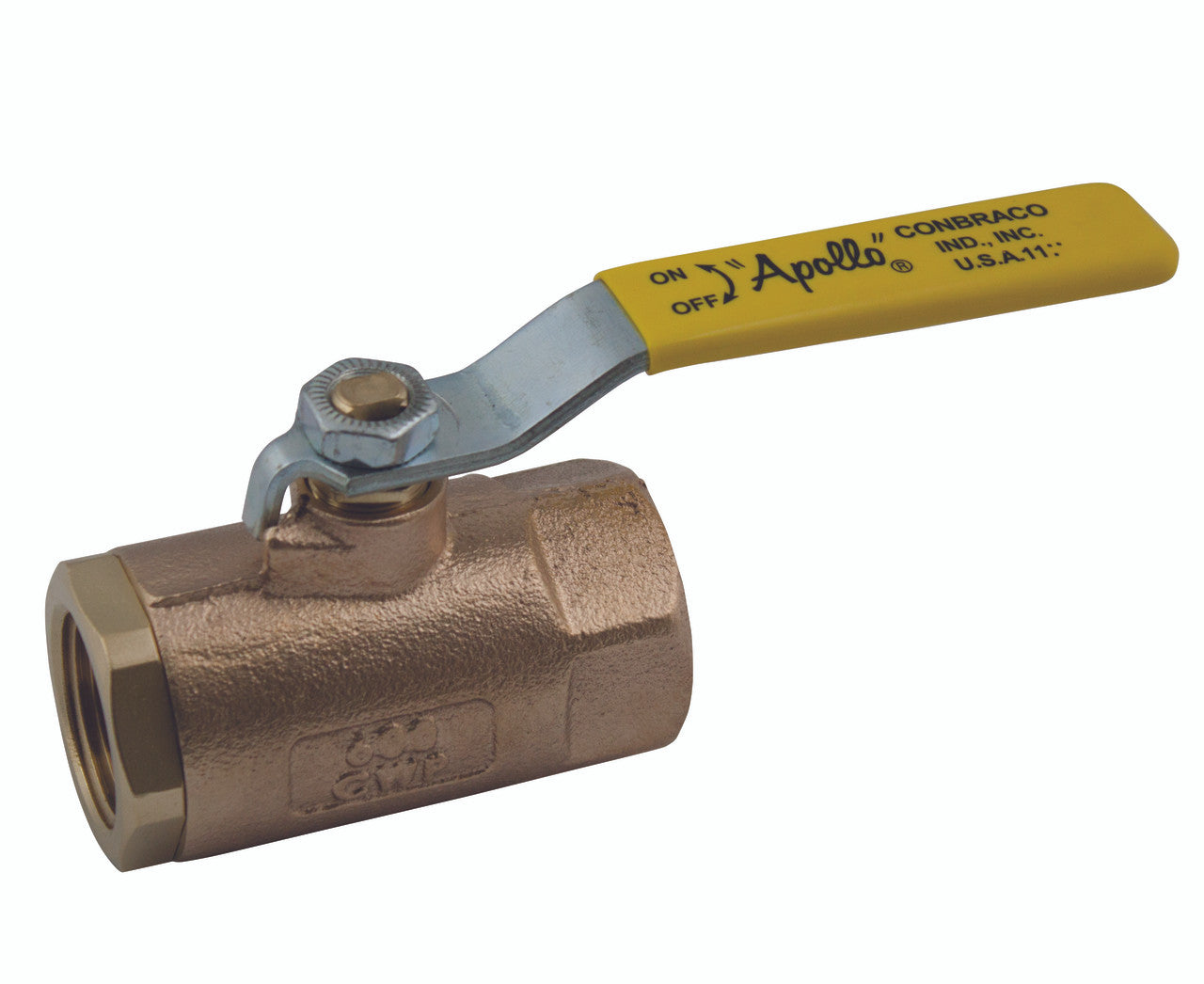

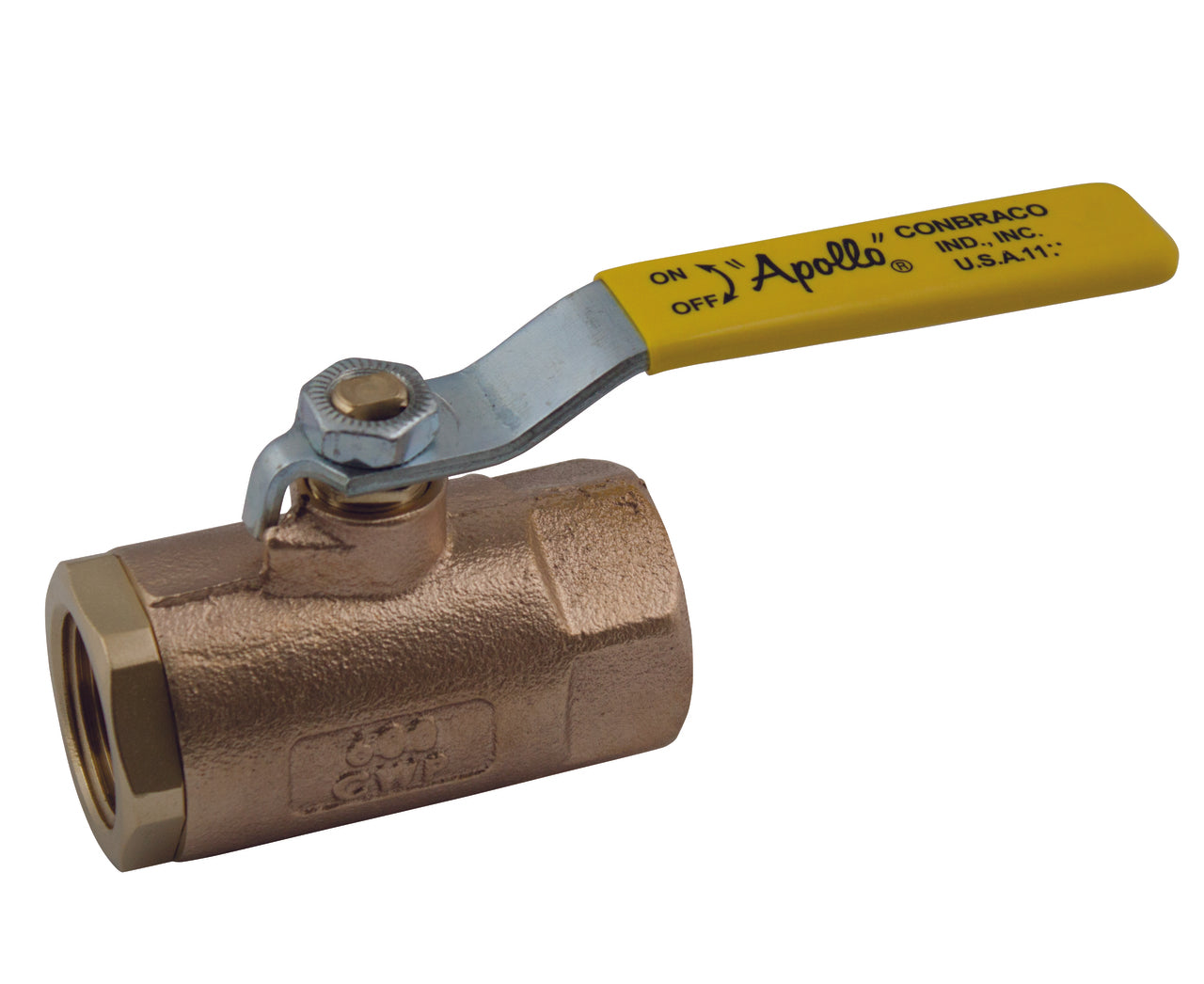

Explore our online catalog, where you'll find a diverse range of valve types, including ball valves, check valves, gate valves, and butterfly valves, each available with threaded, socket weld, sanitary, solder, buttweld, or flanged ends. Whether you're managing fluid flow or controlling processes, we have the right valve to meet your requirements.

Our commitment to quality extends to our esteemed manufacturers and suppliers, which include renowned names like

With such reputable partners, we ensure that every valve you purchase meets the highest standards of performance and reliability.

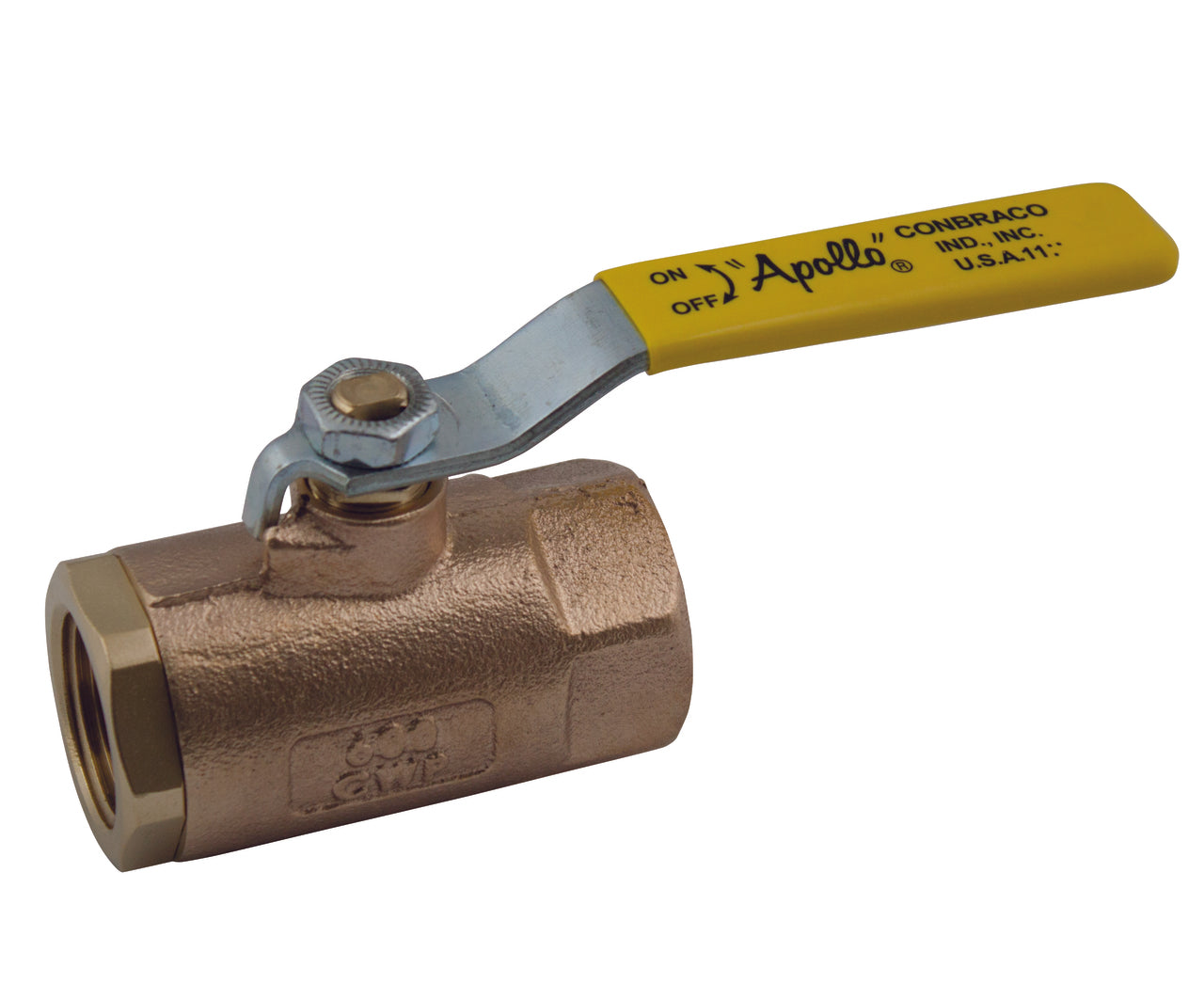

SKU: 00-71-104-01

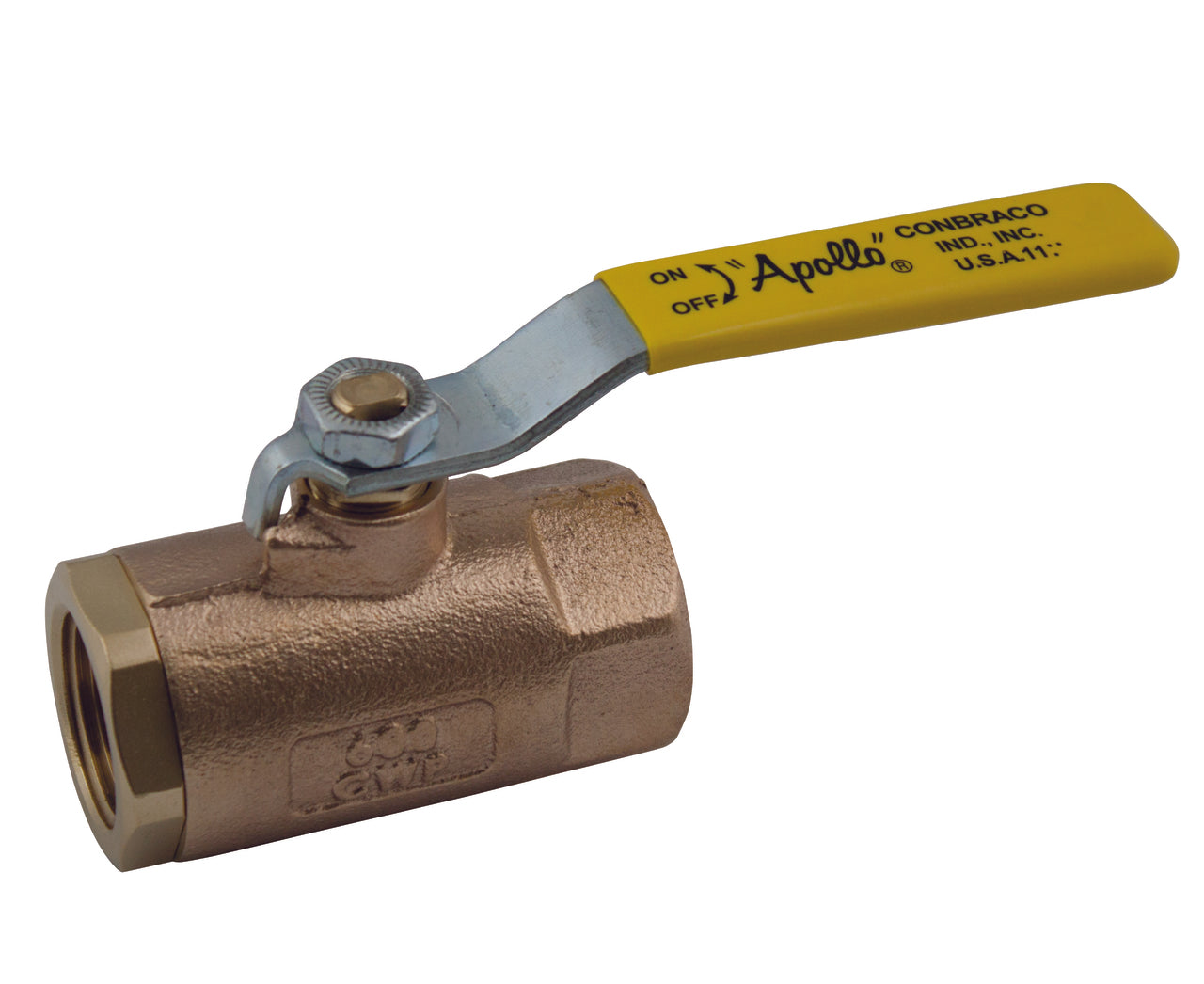

SKU: 00-70-101-47

SKU: 00-70-102-47

SKU: 00-70-103-47

SKU: 00-70-104-47

SKU: 00-70-101-10

SKU: 00-70-143-27

SKU: 00-70-103-10

SKU: 00-70-14A-01

SKU: 00-70-141-01

SKU: 00-70-14A-27

SKU: 00-70-104-27

SKU: 00-77CLF10527A

SKU: 00-70-102-27-41

SKU: 00-70-108-47

SKU: 00-70-142-47

SKU: 00-70-102-27

SKU: 00-70-104-10

SKU: 00-70-107-47

SKU: 00-77CLF14501A

SKU: 00-77V14501

SKU: 00-70-141-47

SKU: 00-70-144-47

In addition to our standard offerings, we also provide lead-free valves and oxygen-cleaned valves, catering to specialized needs and regulatory requirements. We understand that every project is unique, which is why we offer customization options to suit your exact specifications. If you don't find what you're looking for on our website, don't hesitate to reach out to us at info@pipingnow.com. Our team of experts is dedicated to assisting you in finding the perfect valve solution for your project.

What types of valves are suitable for high-pressure applications?

For high-pressure applications, gate valves are often recommended due to their robust construction and ability to withstand extreme pressures. Additionally, ball valves are also suitable for high-pressure environments, offering reliable shut-off capabilities and minimal pressure drop.

Are your valves suitable for use in corrosive environments?

Yes, many of our valves, particularly those made from Stainless Steel, are highly resistant to corrosion, making them ideal for use in corrosive environments. Bronze valves are also suitable for applications where corrosion resistance is crucial.

What are the advantages of butterfly valves over other valve types?

Butterfly valves offer several advantages, including compact design, quick operation, and cost-effectiveness. They are particularly well-suited for applications requiring moderate flow control, such as HVAC systems and water treatment plants.

Do you offer valves compliant with industry standards for lead-free materials?

Yes, we supply a range of lead-free valves that comply with industry standards such as NSF/ANSI 61 and NSF/ANSI 372. These valves are suitable for use in potable water systems and other applications where lead contamination is a concern.

What is the difference between threaded and flanged end valves?

Threaded end valves feature screw threads for easy installation into threaded pipe fittings, offering convenience and versatility. Flanged end valves, on the other hand, are equipped with flanges for bolted connection to pipes or equipment, providing a secure and leak-proof seal in high-pressure applications. Both types have their advantages depending on the specific requirements of your project.

Selecting the appropriate valve depends on factors like media type, pressure, temperature, and required flow control. Consider whether your application requires shut-off, throttling, or backflow prevention. If you're unsure, the PipingNow team is here to assist you in choosing the best solution for your system.

PipingNow offers top-tier industrial valves sourced from leading manufacturers like Apollo, Bonney Forge, and TCI. Our extensive inventory, competitive pricing, and expert support ensure that you get high-quality valves tailored to your project needs—all backed by fast shipping and personalized customer service.

In any liquid or gas system where reverse flow cannot be tolerated, a quick-responding check valve is a necessity. Check valves that close slowly permit flow reversal to occur in the line which can cause severe mechanical shock. As the valve finally seats, high peak pressure pulses and shock waves are generated on the downstream side due to the media being forced to a sudden stop. Upstream, the momentum is not restricted which can create voids in the flow, filling with air or vapor to cause additional, lower frequency shock waves. These shock waves added together are known as water hammer. It can cause extensive damage or failure to pipelines, gaskets, supports, hardware and equipment. The result can be expensive, troublesome; even dangerous.

With Apollo ball cone check valves, the potential for water hammer is greatly reduced since the check returns to its seat before flow velocity reaches zero. Apollo’s check valves set the standard for compact, economical protection against reverse flow. They provide reliable service in liquids or gases at various temperature and pressure combinations. Because of their simple design, they’re versatile and easy to maintain.

Horizontal, vertical or upside down; liquid, air and gases; Apollo’s in-line checks operate in any orientation. Where frequent opening and closing cycles occur, vertical orientation with upward flow is best. This saves time and money, eliminating the need to stock separate vertical and horizontal-operating valves. It also makes new or replacement installation less of a headache.

*Ball cone check valves are not recommended for use with reciprocating pumps and similar applications. Low flows may result in undesirable noise and premature valve failure.

Apollo check valves are at home in applications from residential boilers to tough process systems, including:

Industries where Apollo’s check valves are used include Pulp & Paper, Chemical Processing, Agrichemical, Rubber, Petroleum, Primary Metals, Mining,

Power Generation, Textiles, Food and Beverage, Building Construction and Maintenance.

Backflow preventers valves are devices that are installed prevent contamination of the potable water supply due to back-siphonage or backpressure from substances that are substances that are hazardous.

PipingNow offers both Reduced Pressure Principle Backflow Preventer (RPZ) and Double Check Backflow Valve Preventers (DC).

DCs offer protection against non-health hazards whereas RPZs offer maximum backflow protection for hazardous substances.

Apollo Backflow Preventers Valves are made in the USA and carry a 5-year warranty.

Stainless Steel backflow preventers & Lead-free backflow preventer valves are available too.

Needle valves are valves used to make relatively fine adjustments in the regulation or control of amount of flow. They have a tapered, long, needle-like valve stem that acts as the control mechanism for the ss needle control valves. These needle valves for sale are commonly used in industrial sectors with varying applications such as in pressure pump governors, automatic combustion systems, and instrumentation control.