Copper Fittings

677 products

Showing 1 - 24 of 677 products

PipingNow offers a complete selection of copper fitting options in a variety of shapes, sizes, and configurations to meet the demands of residential, commercial, and industrial plumbing systems. Known for their durability, corrosion resistance, and reliability, these fittings provide a long-lasting, leak-proof solution for water, gas, and HVAC applications.

All fittings are IN STOCK and READY TO SHIP, ensuring fast delivery for your next project.

SKU: 727SECUD01D

SKU: 727SECUD01B

SKU: 727SFCU040

SKU: 727FACU0EX0F

SKU: 727CORCU00B

SKU: 727CORCU00C

SKU: 727CORCU00D

SKU: 727CORCU00E

SKU: 727CORCU00F

SKU: 727CORCU00A

SKU: 727CORCU00J

SKU: 727CORCU010

SKU: 727CORCU01B

SKU: 727CORCU00G

SKU: 727COSCU00C

SKU: 727CORCU020

SKU: 727COSCU00D

SKU: 727CORCU01D

SKU: 727COSCU00F

SKU: 727COSCU00E

SKU: 727COSCU00B

SKU: 727COSCU01B

SKU: 727COSCU00G

SKU: 727COSCU010

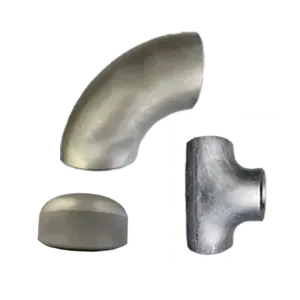

Types of Copper Fittings

Our pipe fitting copper products are available in many forms to suit different installation needs. We carry all major types, including:

- Elbows (45°, 90°, street elbows)

- Tees

- Couplings / Unions

- Reducers / Adapters

- Flanges, caps & unions

Applications of Copper Fittings

Copper applications are widely used in both residential and commercial plumbing systems. Their versatility and strength make them ideal for:

- Hot and cold water supply lines

- Heating and cooling (HVAC) systems

- Gas distribution lines

- Refrigeration and compressed air systems

They are particularly valued in environments where a secure, leak-proof, and corrosion-resistant connection is essential.

Copper Fittings Sizes and Standards

All our fittings adhere to recognized industry standards (ASME, ASTM, MSS) to ensure compatibility and performance.

Available in:

- Type K, L, and M for different wall thicknesses and pressure ratings

- Sizes ranging from 1/8" to 8" nominal diameter

Always refer to standard sizing charts to ensure the proper fit for your system requirements.

Benefits of Copper Fittings

- Corrosion Resistance: Withstands moisture and chemical exposure for long service life.

- Heat Tolerance: Performs reliably in both hot and cold water systems.

- Ease of Installation: Simple to solder, braze, or press-fit.

- Hygienic and Safe: Naturally inhibits bacterial growth, making it ideal for potable water.

- Recyclable Material: Environmentally friendly and sustainable.

How to Choose the Right Copper Fitting

Selecting the correct copper fitting depends on:

- Application: Determine if it’s for water, gas, or HVAC use.

- Pressure and Temperature: Match the fitting’s rating to system conditions.

- Pipe Size and Type: Confirm compatibility with copper tube (Type K, L, or M).

- Connection Method: Choose between solder, compression, or press fittings.

When in doubt, consult sizing charts or reach out to our team for expert guidance.

Buy Copper Fittings Online

Shop our full range of pipe fittings. Whether you need fittings for new construction or maintenance projects, PipingNow has the products and expertise to keep your systems running smoothly.

FAQs

What are the different types of copper fittings?

Elbows, tees, couplings, reducers, and adapters are the most common types, available in various sizes and configurations.

What are the advantages of using copper fittings in plumbing?

They provide durability, corrosion resistance, heat tolerance, and a leak-free seal—ideal for long-term performance.

Where can copper fittings be used?

They’re suitable for water, gas, HVAC, and refrigeration systems in both residential and commercial applications.

How do I select the right size of copper fitting?

Match the fitting to the pipe’s nominal size and wall type (K, L, or M). Refer to the manufacturer or ASTM sizing charts.

Are copper fittings suitable for hot and cold water lines?

Copper is widely used in both hot and cold water supply systems due to their thermal stability.

Can copper fittings be used for gas or HVAC systems?

They can be used provided the fittings meet applicable pressure and temperature ratings for the specific system.

How do I install copper fittings properly?

Clean and prep the tube ends, apply flux, and solder or braze securely. For press fittings, follow the manufacturer's instructions using proper tools.