A 1/2 ball valve is one of the most widely used components in fluid control systems, offering a reliable way to start or stop flow in pipelines, plumbing systems, and industrial processes. Compact, versatile, and durable, this type of valve is found in applications ranging from household plumbing to large-scale chemical operations. Understanding its features, functions, and variations helps professionals and homeowners alike make better choices for safe and efficient fluid management.

What Is a 1/2 Ball Valve?

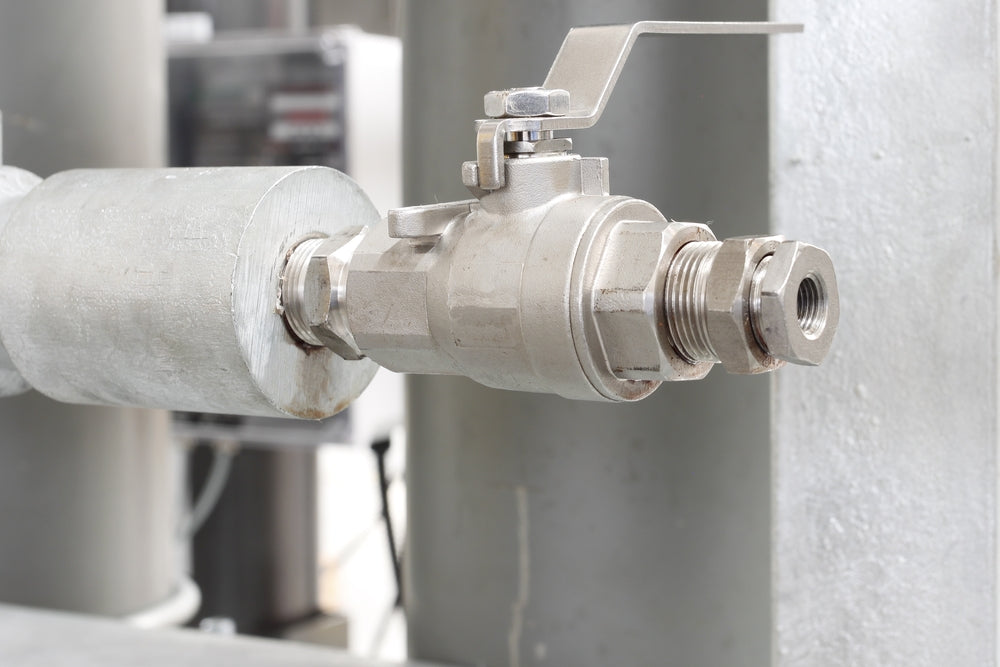

A 1/2 ball valve is a quarter-turn valve designed with a spherical ball inside that controls the flow of liquid or gas. The ball has a hole, or port, through the middle. When aligned with the pipe, flow passes through; when rotated 90 degrees, the valve closes. Its straightforward operation, minimal resistance, and quick shutoff capabilities make it one of the most popular plumbing valves available today.

Common Uses of a 1/2 Ball Valve

Ball valves are highly adaptable, fitting into multiple environments where dependable shutoff is critical. A closer look at their most common applications highlights why they are so widely trusted.

Residential Plumbing – Water Shutoff, Sink and Toilet Connections

In homes, a 1/2 ball valve is commonly installed on water supply lines for sinks, toilets, dishwashers, and washing machines. Its compact size and quarter-turn mechanism make it an excellent choice for situations where homeowners need reliable shutoff without complicated tools or adjustments.

Industrial Applications – Chemical, Oil & Gas, and Manufacturing

In factories and heavy-duty work environments, a 1/2 ball valve is often used in systems handling chemicals, petroleum, and pressurized fluids. As an industrial ball valve, it can withstand high pressures and temperatures while maintaining leak-proof performance. This reliability makes it indispensable for safety and efficiency in critical operations.

Commercial Use – HVAC Systems, Compressed Air Systems

Commercial facilities like office buildings, hospitals, and schools depend on efficient heating, cooling, and ventilation systems. Within HVAC piping and compressed air networks, a 1/2 ball valve ensures smooth flow control and quick isolation during maintenance. Its durability ensures long-term operation in demanding conditions.

DIY and Small Projects – Garden Hoses, Home Brewing, Aquariums

Outside of professional settings, smaller projects also benefit from the straightforward functionality of a 1/2 ball valve. Gardeners use them to control hose attachments, hobbyists rely on them for aquariums or brewing equipment, and DIY enthusiasts value them for their dependability in custom projects. In these cases, ball valve uses are simple yet highly effective.

Benefits of Using a 1/2 Ball Valve

-

Corrosion Resistance – The internal and external surfaces are designed to resist rust and chemical damage, ensuring performance in water systems, gas lines, and industrial pipelines. This makes them especially reliable in environments where longevity is crucial.

-

Reliable Seal – Thanks to the precision-engineered spherical ball, these valves maintain a tight seal that prevents leaks, even under high pressure or after thousands of open-and-close cycles. This reliability reduces downtime and the risk of costly repairs.

-

Low Maintenance – Unlike some other valve types that require regular lubrication or adjustments, a 1/2 ball valve functions smoothly with minimal upkeep. This simplicity lowers overall operational costs while saving time for both homeowners and facility managers.

-

Balanced Design – Compared to other ball valve sizes, the 1/2 option delivers an ideal combination of compactness and flow efficiency. It fits into small spaces while still allowing a strong, consistent flow of liquids or gases.

-

Durability Under Pressure – These valves are engineered to withstand significant pressure ratings, making them suitable for demanding applications such as hydraulic systems, compressed air networks, or chemical processing plants.

-

Versatile Application – The same valve can serve a wide range of ball valve uses, from residential shutoffs to industrial process control. This versatility makes it a go-to choice for contractors, engineers, and DIY enthusiasts alike.

-

Quick Shutoff – Its quarter-turn operation allows for rapid response in emergencies, which is essential when dealing with gas leaks, burst pipes, or other urgent situations requiring immediate isolation of flow.

-

Energy Efficiency – With minimal flow resistance, a 1/2 ball valve reduces pressure drops within the system. This efficiency can help lower energy consumption in pumps and compressors, providing long-term savings in commercial and industrial setups.

Materials and Options for 1/2 Ball Valves

Ball valves are manufactured in different materials to suit various applications. Brass and PVC are common for residential uses, offering affordability and resistance to water corrosion. For harsher environments, a stainless steel ball valve provides maximum durability, resisting chemical damage and maintaining structural integrity under high temperatures and pressures. Options may also include threaded, soldered, or press connections, ensuring compatibility with diverse systems.

Choosing the Right 1/2 Ball Valve

Selecting the right ball valve requires more than just matching the size. Consider the medium being transported, pressure requirements, temperature range, and material compatibility. For example, chemical processing often demands valves made from stainless steel, while irrigation systems can function effectively with brass or PVC. Evaluating these needs ensures not only safety but also long-term efficiency. Reliable ball valve uses depend on choosing the correct product for the application.

Frequently Asked Questions

What is the difference between a 1/2 ball valve and a gate valve?

A 1/2 ball valve uses a spherical mechanism for quick shutoff with just a quarter-turn, while a gate valve relies on a rising or lowering gate to control flow. Ball valves provide faster operation and a tighter seal, making them preferable in most settings.

Can a 1/2 ball valve be used for gas lines?

A properly rated 1/2 ball valve can indeed handle natural gas or propane lines. The key consideration is material compatibility and certification. Valves specifically tested and approved for gas service ensure safe performance in both residential and commercial applications.

What’s the lifespan of a stainless steel 1/2 ball valve?

A stainless steel ball valve can last several decades under normal operating conditions, often exceeding 20 years. Its resistance to rust, pitting, and chemical corrosion allows it to perform reliably in demanding industrial and residential systems with minimal maintenance.

Are ball valves better than traditional shutoff valves?

Ball valves often outperform traditional shutoff valves due to their durability, leak-resistant seals, and ease of use. Unlike compression or globe valves, they require only a quarter-turn to operate and maintain consistent performance across a variety of applications.

PipingNow’s 1/2 Ball Valve Selection

Choosing the right 1/2 ball valve ensures efficiency, safety, and durability across residential, commercial, and industrial applications. With options in stainless steel, brass, and PVC, you’ll find solutions tailored to your needs and backed by trusted expertise.

Explore our full range of 1/2 ball valves today. From durable materials to precise engineering, we have the right fit for every project—contact us now to get started.